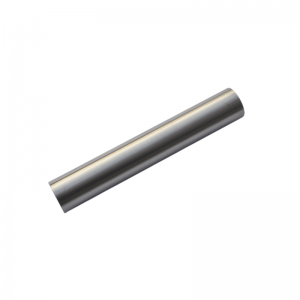

Molybdenum Rod uye Molybdenum Alloy Rod

Molybdenum Rod uye Molybdenum Alloy Rod

Matanda edu emolybdenum akagadzirwa nepamusoro-kuchena molybdenum poda, ine zvishoma zvinyoro zvemukati mubillet, yakakwira sintering density, deformation yakakura yechigadzirwa chakagadzirwa, uye kutonga kwakanaka kwemaitiro ekugadzira.Matanda edu e molybdenum ane hunhu hwekupikisisa kwepamusoro-tembiricha, kusimba kwepamusoro, saizi yakanaka yezviyo, uye nyore kugadzirisa.

Molybdenum tsvimbo inogona kukamurwa kuva:

•Pure molybdenum tsvimbo: iyo molybdenum inodarika 99,95%.

•High-temperature molybdenum rod (molybdenum-lanthanum alloy rod): 0.4 ~ 1.2% lanthanum, uye zvinyorwa zvemolybdenum ndiyo chiyero kunze kwekusvibiswa.

•TZM molybdenum tsvimbo: 0.4~0.6%Ti, 0.07~0.12%Zr, 0.01~0.05%C.

Molybdenum Rod Ruzivo

| Products Name | Molybdenum Rod |

| Standard | GB/T 17792-2014, ASTM B387-90(2001) |

| Material | Mo, MoLa, TZM |

| Kuchena | 99.95% |

| Density | 10.2g/cm³ |

| Operating Temperature | 1100 ℃ ~ 1800 ℃ |

| Surface | Musoro wakasviba, Alkali wash, wakakwenenzverwa |

| Tsanangudzo | Diameter(φ2~φ200mm)×Kureba(10~3000mm) |

| MOQ | 1Kg, saizi yakasarudzika iripo |

Dimensional Tolerances

| Surface | Diameter | Diameter Tolerance | Urefu | Kureba Kushivirira | Kukasharara |

| Forged | Φ2~Φ250 | ±1±2 | 10~3000 | ±1±2 | Ra≤3.2 |

| Lathed | Φ2~Φ200 | ±0.01±0.05 | 10~3000 | ±0.01±1 | Ra≤1.6 |

| Kukuya | Φ2~Φ80 | ±0.01±0.05 | 10~3000 | ±0.01±1 | Ra≤0.8 |

Molybdenum Rod Application

•Semiconductor ion implantation components.

•Electric light source uye electric vacuum parts.

•Industrial high-temperature choto refractory zvikamu.

•Girazi choto chemoto molybdenum electrode.

•Inoshandiswa se electrode mune isingawanzo indasitiri yepasi.

Isu tinopa yakakwirira-kuchena molybdenum tsvimbo uye molybdenum alloy tsvimbo, inotengeswa makirogiramu, fekitori-yakagadzirwa, nemitengo yakanaka, uye inotsigira saizi yakajairwa uye nzvimbo, ndapota taura nesu kana uchizvida.

Unoda kuziva zvakawanda nezvezvigadzirwa zvedu?

Ndibate

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Runhare: 0086 156 1977 8518(WhatsApp/Wechat)

Kana iwe uchida kuziva mamwe mashoko uye mitengo yezvigadzirwa zvedu, tapota taura nemutungamiriri wedu wekutengesa, iye achakupindura iwe nokukurumidza sezvinobvira (kazhinji kwete kupfuura 24h), ndatenda.