PVD Coating

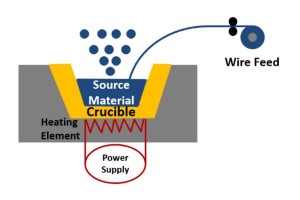

PVD (Physical Vapor Deposition) tekinoroji inoreva kushandiswa kwemaitiro emuviri pasi pevacuum mamiriro ekuputira pamusoro pechinhu chinobva (chakasimba kana mvura) kuita maatomu egasi kana mamorekuru, kana kuti ionize kuita ion, uye kuburikidza negasi-rinodzvinyirira. kana plasma) process, Tekinoroji inoisa mafirimu matete ane mamwe mabasa akakosha pamusoro pe substrate.PVD (Physical Vapor Deposition) ndiyo huru yekurapa tekinoroji inoshandiswa zvakanyanya mukugadzirisa kwepamusoro, kushanda, kushongedzwa, nezvimwe zvezvinhu mumaindasitiri akasiyana.

PVD (physical vapor deposition) tekinoroji yekuputira inonyanya kukamurwa kuita zvikamu zvitatu: vacuum evaporation coating, vacuum sputtering coating, uye vacuum ion plating.Nzira huru dzekuisa mhute yemuviri dzinosanganisira vacuum evaporation, sputtering coating, arc plasma coating, ion coating, etc. Inopindirana vacuum coating equipment inosanganisira vacuum evaporation coating machines, vacuum sputtering coating machines, uye vacuum ion coating machines.

Zvigadzirwa zvedu zvine hukama zvinosanganisira maelectron beam crucible liners, tungsten evaporation filaments, electron gun tungsten filaments, evaporation boats, evaporation materials, sputtering targets, etc.

Vacuum Furnace

Choto chevacuum chinoshandisa vacuum system (yakanyatso kuunganidzwa kubva pavacuum pombi, vacuum yekuyera midziyo, vacuum mavharuvhu, uye zvimwe zvinhu) munzvimbo chaiyo yechoto mhango kuti ibudise chikamu chechinhu mugomba rechoto kuitira kuti kumanikidza muchoto. mhango ishoma pane imwechete yakajairwa atmospheric pressure., nzvimbo iri muchoto chechoto inoshandiswa kuti iwane nzvimbo yevacuum, iyo inopisa moto.

A vacuum furnace ndeye vacuum kupisa kupisa kwevira, iyo inosiyaniswa zvinoenderana nekushandiswa kwayo uye inosanganisira anotevera marudzi:

Vacuum quenching choto, vacuum brazing choto, vacuum annealing choto, vacuum magnetizing choto, vacuum tempering choto, vacuum sintering choto, vacuum diffusion welding choto, vacuum carburizing choto, nezvimwe.

Vacuum furnaces inonyanya kushandiswa kupfutidza ceramic, vacuum smelting, electric vacuum parts degassing, annealing, brazing of metal parts, ceramic-metal sealing, physical vapor deposition (PVD), nezvimwewo.

Isu tinopa zvinhu zvekudziya, Boat Trays uye Vanotakura, nhovo dzekupisa, crucibles uye liner, tungsten filaments uye evaporation masosi, fasteners, uye nezvimwe, zvinowanikwa mu tungsten, molybdenum, kana tantalum zvinhu, uye zvinogona kugadzirwa.

Photovoltaic & Semiconductor

Imwe-crystal silicon yekukura vira, inozivikanwawo sesilicon crystal yekukura vira kana silicon ingot vira, chinhu chakakosha chinoshandiswa muphotovoltaic uye semiconductor maindasitiri kugadzira emhando yepamusoro imwe-crystal silicon ingots.Monocrystalline silicon ndiyo yakakosha zvinhu zvekugadzira semiconductor zvishandiso senge akasanganiswa maseketi (ICs), maseru ezuva, uye masensa.

Iyo "Czochralski nzira" parizvino ndiyo inonyanya kushandiswa nzira yekugadzira imwe-crystal silicon.

Paunenge uchigadzira imwe-crystal silicon uchishandisa nzira yeCzochralski (CZ method), tanga waisa high-purity polycrystalline silicon mu quartz crucible, mirira kuti polycrystalline silicon inyauke muchoto chekristaro chimwe chete, uye wozogadzirisa mbeu yekristaro pambeu. axis uye woiisa mukati meiyo mhinduro.Yakamirira kusanganiswa kwekristaro yemhodzi uye mhinduro, silicon inotanga kusimba pakristaro yemhodzi uye inokura pamwe chete nelattice chimiro chekristaro yembeu kuti igadzire single-crystal silicon.Munguva iyi, kristaro yembeu inoda kudhonzwa zvishoma nezvishoma kuti ibvumire iyo-crystal silicon kuti irambe ichikura.

Isu tinopa molybdenum mbeu tsvimbo, tungsten uye molybdenum crucible liners, fasteners, molybdenum hooks, tungsten carbide sando, nezvimwe.

Girazi Uye Rare Earth

Indasitiri yegirazi inoita basa rakakosha munharaunda yemazuva ano, ichipa zvinhu zvakakosha zvekuvaka, zvekufambisa, tekinoroji, hutano hwehutano, uye kurongedza uku uchityaira hunyanzvi, kusimba, uye kukura kwehupfumi.

Tinogona kupa molybdenum electrodes yekunyunguduka kwegirazi.Inowanzoshandiswa molybdenum electrode madiyamita kubva 20mm kusvika 152.4mm, uye kureba imwe electrode anogona kusvika 1500mm.Isu tinokwanisa kupa alkali-yakagezwa nzvimbo, muchina-yakakwenenzverwa nzvimbo, nezvimwe.

Indasitiri yepasi isingawanzo zvinosanganisira kudhirowa, kugadzirisa, uye kushandiswa kwezvinhu zvisingawanzo pasi, izvo zvakakosha mukusimudzira hunyanzvi hwetekinoroji uye kutsigira shanduko kune yakaderera-kabhoni, yepamusoro-tech hupfumi.Rare pasi zvinhu zvinhu zvakakosha zveakasiyana matekinoroji uye maapplication.

Tinogona kupa tungsten, molybdenum, uye tantalum kudziyisa zvinhu;sintered tungsten, molybdenum crucibles uye graphite crucibles, nezvimwe.

Zviridzwa & Meter Zvishandiso

● Metal diaphragms inonyanya kushandiswa mu diaphragm pressure gauge uye transmitters.Zvinhu zvatinogadzira zvinosanganisira SS316L, tantalum, titanium, HC276, Monel400, uye Inconel625.

● Signal electrodes anonyanya kushandiswa mu electromagnetic flowmeters.Saizi ye electrode ndeye M3 ~ M8, uye zvigadzirwa zvinosanganisira SS316L, tantalum, titanium, uye HC276.

● Ground Electrode, iyo inonziwo pasi ring, inonyanya kushandiswa mumagetsi emagetsi emagetsi uye anowanzoshandiswa ari maviri.Saizi inobva kuDN25~DN600, uye zvinhu zvacho zvinosanganisira SS316L, tantalum, titanium, uye HC276.

● Diaphragm-yakavharwa flange, kazhinji ine diaphragm chisimbiso kuti iparadzanise sero rekuyeresa kubva pakati.Flange zvinhu zvatinogadzira SS316L, Titanium, HC276, uye Tantalum.Teerera neASME B 16.5, DIN EN 1092-1, uye mamwe maitiro.

Unoda kuziva zvakawanda nezvezvigadzirwa zvedu?

Taura nesu

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Runhare: +86 156 1977 8518 (WhatsApp/Wechat)

Kana iwe uchida kuziva mamwe mashoko uye mitengo yezvigadzirwa zvedu, tapota taura nemutarisiri wedu wekutengesa, iye achakupindura iwe nokukurumidza sezvinobvira (kazhinji kwete kupfuura 24h), ndatenda.