Tungsten filament yekugadzirisa fekitori ye vacuum metallization

Tungsten filament yekubvisa simbikugadzirisa fekitari,

Tungsten filament yekubvisa simbi,

Filaments dzeTungsten Evaporation

Tungsten evaporation filaments inonyanya kushandiswa mu vacuum metallization processes. Vacuum metallization inzira inoumba simbi firimu pa substrate, ichiputira simbi (yakadai searuminiyamu) pa substrate isiri yesimbi nekupisa evaporation.

Tungsten ine hunhu hwekunyunguduka kwakanyanya, kuramba kwakasimba, simba rakanaka, uye kumanikidzwa kwakaderera kweutsi, zvichiita kuti ive chinhu chakanakira kugadzira manyuko eutsi.

Makoiri emuchadenga eTungsten anogadzirwa netambo imwe chete kana dzakawanda dzewaya yetungsten uye anogona kukotama kuita maumbirwo akasiyana zvichienderana nezvinodiwa nemi pakuisa kana kupwanya. Tinokupai mhinduro dzakasiyana-siyana dzetambo yetungsten, tinokugamuchirai kuti mutibate kuti muwane mitengo yakasarudzwa.

Tungsten Filaments Ruzivo

| Zita rechigadzirwa | Filaments dzeTungsten Evaporation |

| Kuchena | W≥99.95% |

| Kuwanda kwevanhu | 19.3g/cm³ |

| Nzvimbo Yokunyunguduka | 3410°C |

| Tambo | φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, Inogona kugadziriswa. |

| MOQ | 3Kg |

| Cherechedza: Maumbirwo akakosha etungsten filaments anogona kugadziriswa zvichienderana nezvaunoda. | |

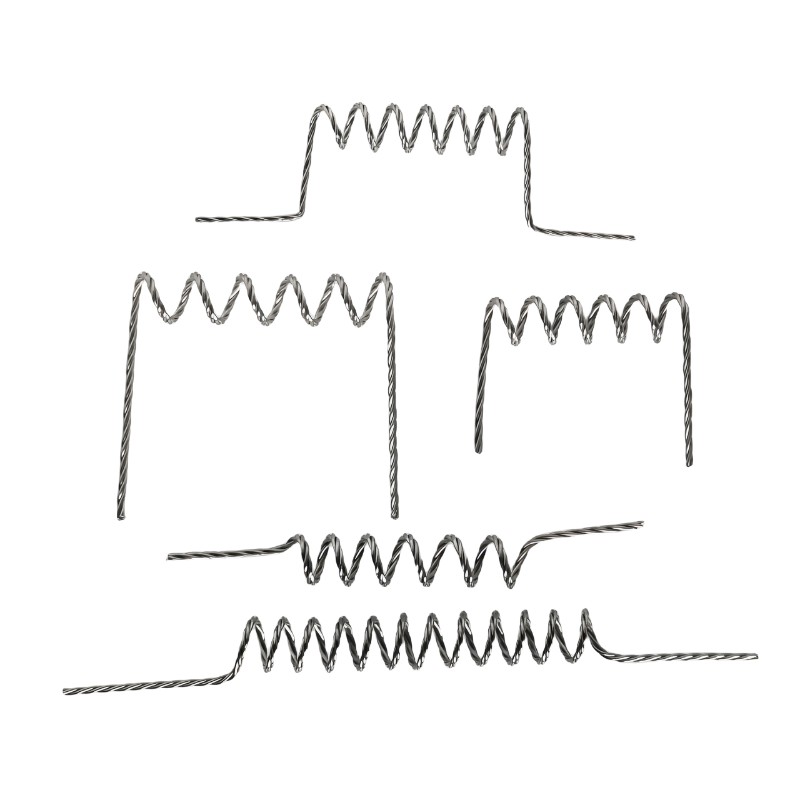

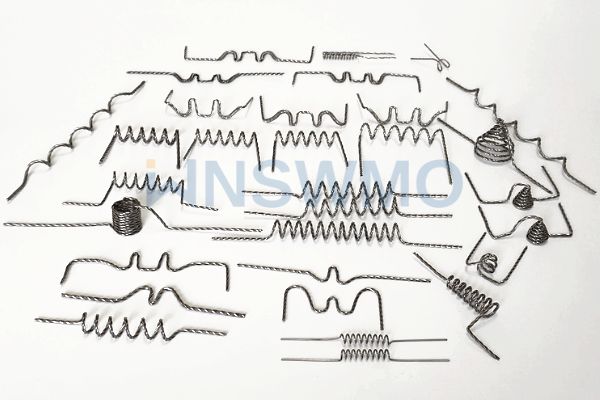

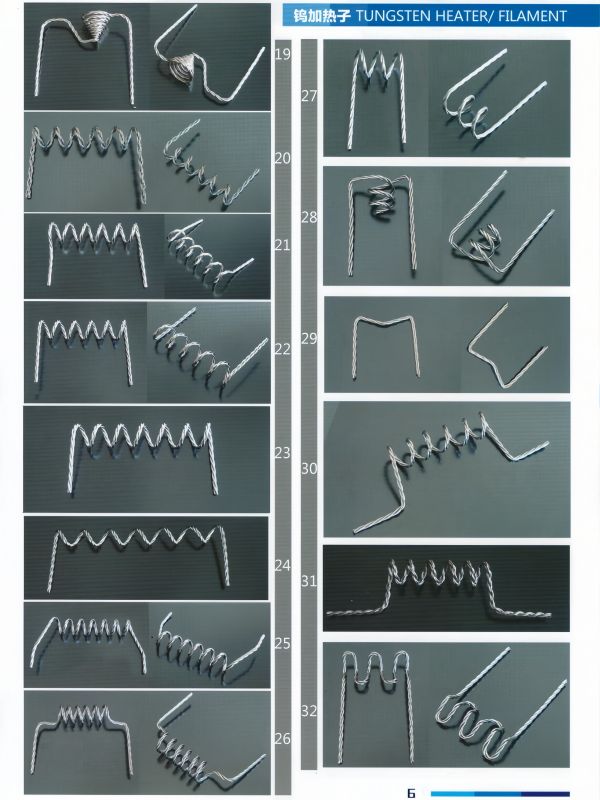

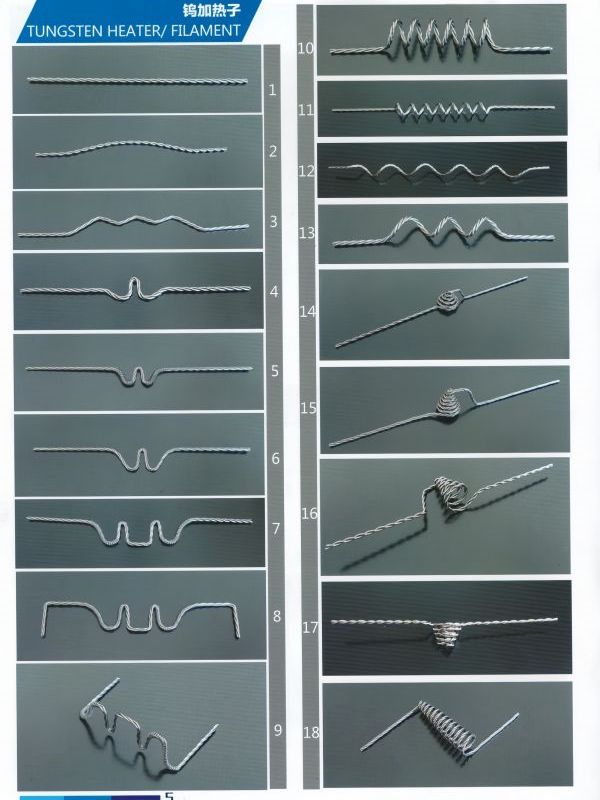

Mifananidzo yeTungsten Filaments

Mifananidzo yeTungsten Filament (Dzvanya kuti uone)

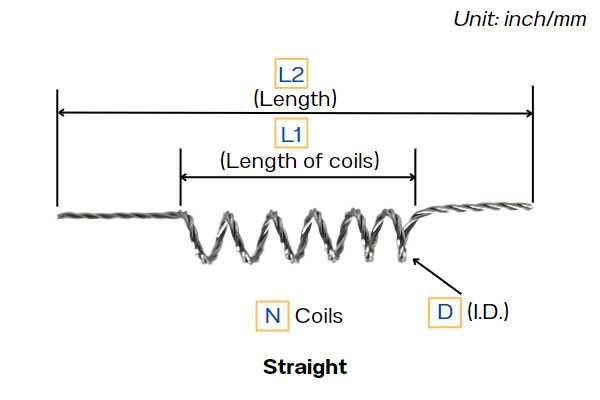

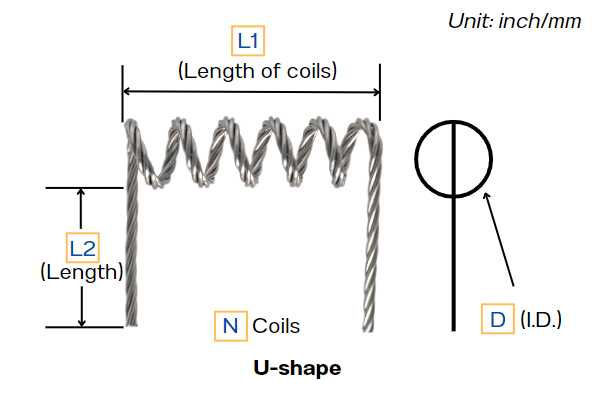

Cherechedza: Mufananidzo uyu unongoratidza chete shinda dzakatwasuka uye dzakaita seU, zvichikubvumidza kugadzirisa mamwe marudzi nehukuru hweshinda dzakaita setungsten, kusanganisira shinda dzakaita sepeak-shaped, nezvimwewo.

| Chimiro | Yakatwasuka / Yakaumbwa neU, Inogona kugadziriswa |

| Nhamba yeTanda | 1, 2, 3, 4 |

| Makoiri | 4, 6, 8, 10 |

| Dhayamita yeWaya (mm) | φ0.76, φ0.81, φ1 |

| Kureba kweCoils | L1 |

| Kureba | L2 |

| ID yeCoils | D |

| Cherechedza: mamwe magadzirirwo uye maumbirwo efilament anogona kugadziriswa. | |

Sarudza tungsten filament inokukodzera, uye tinogona kuigadzirisa. Nguva yekugadzirisa ipfupi semazuva gumi, uye huwandu hushoma hweodha i3 kg chete (mutengo wekutengesa).

Mashandisirwo eTungsten Evaporation Filament

| • Kugadzira Makonductor Ezvinhu Zvishoma | • Kuisa Mafirimu Matete eMagetsi | • Tsvagiridzo neKuvandudza |

| • Kuputira kwemaziso | • Kugadzira Masero Ezuva | • Mapendi Ekushongedzera |

| • Kugadzira Simbi neVacuum Metallurgy | • Indasitiri yeNdege | • Indasitiri yeMotokari |

Ndezvipi zvakanakira Tungsten Evaporation Filaments?

Tinogona kupa mhando dzakasiyana dzeTungsten Thermal Filament Sources, unogona kudzidza nezvezvigadzirwa izvi kuburikidza nekatalogu yedu, tinokugamuchirai kuti mutibvunze.

Tinopa manyuko emvura uye zvinhu zvekubuda kwemvura zvePVD coating & Optical coating, zvigadzirwa izvi zvinosanganisira:

| Matanda eElectron Beam Crucible Liners | Tungsten Coil Heater | Filament yeTungsten Cathode |

| Chinopfuta Kupisa Kwemvura | Zvinhu zveKubuda Kwemvura | Chikepe cheKubuda Kwemvura |

Hauna chigadzirwa chaunoda here? Ndapota taura nesu, tichagadzirisa dambudziko racho.

Kubhadhara & Kutumira

→KubhadharaTsigira T/T, PayPal, Alipay, WeChat Pay, nezvimwewo. Ndapota tauriranai nesu kuti muwane dzimwe nzira dzekubhadhara.

→KutumiraTsigira FedEx, DHL, UPS, zvinhu zvinotakura mugungwa, uye zvinhu zvinotakura mundege, unogona kugadzirisa hurongwa hwako hwekufambisa, uye tichakupawo nzira dzekufambisa dzakachipa kuti uzive.

Unoda kuziva zvakawanda nezvezvigadzirwa zvedu here?

Taura nesu

Maneja weKutengesa waAmanda│

E-mail: amanda@winnersmetals.com

Nhare: +86 156 1977 8518 (WhatsApp/ Wechat)

Kana muchida kuziva zvakawanda nezvemitengo yezvigadzirwa zvedu, ndapota taurai nemaneja wedu wekutengesa, achakupindurai nekukurumidza sezvinobvira (kazhinji mukati memaawa gumi nemaviri), zvechokwadi, munogonawo kudzvanya "KUMBIRA VATENGESI VATENGESI", kana kutibata zvakananga nekutumira email (Email:info@winnersmetals.com).

Tungsten evaporation filaments inonyanya kushandiswa mu vacuum metallization processes, iyo iri yePVD processes.

Zvigadzirwa zvedu zvetungsten filament zvinoshandisa nzira dzepamusoro dzekugadzira kuti zvive nechokwadi chekuti batch yega yega yakachena uye yakafanana. Tinoziva kuti zvinhu zvemhando yepamusoro chete ndizvo zvinogona kuzadzisa zvinodiwa zvako zvakasimba pakushanda kwechigadzirwa. Saka, tinoita bvunzo dzakasimba uye kutonga mhando pabatch yega yega yetungsten tambo kuti ive nechokwadi chekuti inoshanda zvakanaka uye yakavimbika.

Kunyangwe muchida saizi dzakagadzirwa uye zvirevo kana ma parameter chaiwo ekushanda, tinogona kupa mhinduro dzehunyanzvi uye masevhisi akagadzirwa. Chikwata chedu chine ruzivo rwakakura muindasitiri uye chinogona kupa zvigadzirwa zve tungsten filament zvakakodzera zvinoenderana nezvamunoda.

Kusarudza tungsten filaments dzedu kusarudza kuzvipira kune mhando yepamusoro uye kutsvaga kugona. Tinotarisira kushanda nemi pamwe chete kukurudzira kuvandudzwa kwehunyanzvi hwekugadzira zvinhu nemazvo uye kugadzira ramangwana rakanaka.

Tibate izvozvi kuti udzidze zvakawanda nezve tungsten filaments kana kukumbira sampuro dzekuyedzwa. Isu takagadzirira kukupa mazano ehunyanzvi uye sevhisi.