Tungsten Filament Evaporation Coils yeVacuum Metallization

Tsananguro yeChigadzirwa

Tungsten evaporation filaments inonyanya kushandiswa mu vacuum metallization processes. Vacuum metallization inzira inoumba simbi firimu pa substrate, ichiputira simbi (yakadai searuminiyamu) pa substrate isiri yesimbi nekupisa evaporation.

Tungsten ine hunhu hwekunyunguduka kwakanyanya, kuramba kwakasimba, simba rakanaka, uye kumanikidzwa kwakaderera kweutsi, zvichiita kuti ive chinhu chakanakira kugadzira manyuko eutsi.

Makoiri emuchadenga eTungsten anogadzirwa netambo imwe chete kana dzakawanda dzewaya yetungsten uye anogona kukotama kuita maumbirwo akasiyana zvichienderana nezvinodiwa nemi pakuisa kana kupwanya. Tinokupai mhinduro dzakasiyana-siyana dzetambo yetungsten, tinokugamuchirai kuti mutibate kuti muwane mitengo yakasarudzwa.

Ndezvipi zvakanakira Tungsten Evaporation Filaments?

✔ Nzvimbo Yakanyanya Kunyunguduka

✔ Kugadzikana Kwakanaka Kwekupisa

✔ Kubuda Kwemaerekitironi Kwakanaka

✔ Kusashanda kwemakemikari

✔ Kufambiswa Kwemagetsi Kwakanyanya

✔ Simba reMichina

✔ Kumanikidzwa kwemhepo kwakaderera

✔ Kuenderana Kwakakura

✔ Nguva Yeupenyu Hurefu

Mashandisirwo

• Kugadziriswa kwesimbi ne vacuum:Inoshandiswa pakugadzira simbi pamusoro pepurasitiki nesimbi (senge zvikamu zvemota), zvichiita kuti ifukidzwe zvakaenzana kuburikidza nekupwanya simbi inopisa zvakanyanya.

• Midziyo ye semiconductor uye vacuum:Inoshandiswa zvakananga sezvinhu zvinodziisa mukugadzira semiconductor kana zvishandiso zvemagetsi zvinopisa (senge ma electron tube cathodes), zvichiita kuti pave nenzvimbo inodziya zvakanyanya.

Magadzirirwo

| Zita rechigadzirwa | Filament yeTungsten yekubuda kwemvura |

| Kuchena | W≥99.95% |

| Kuwanda kwevanhu | 19.3g/cm³ |

| Nzvimbo Yokunyunguduka | 3410°C |

| Nhamba yeTanda | 2/3/4 |

| Dhayamita yewaya | 0.6-1.0mm |

| Chimiro | Yakagadzirirwa zvinoenderana nemifananidzo |

| MOQ | 3Kg |

| Cherechedza: Maumbirwo akakosha etungsten filaments anogona kugadziriswa zvichienderana nezvaunoda. | |

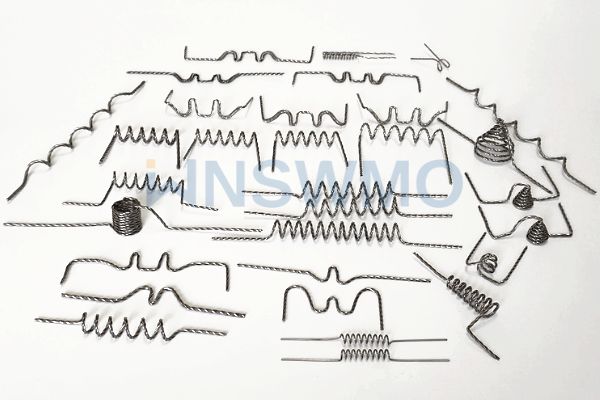

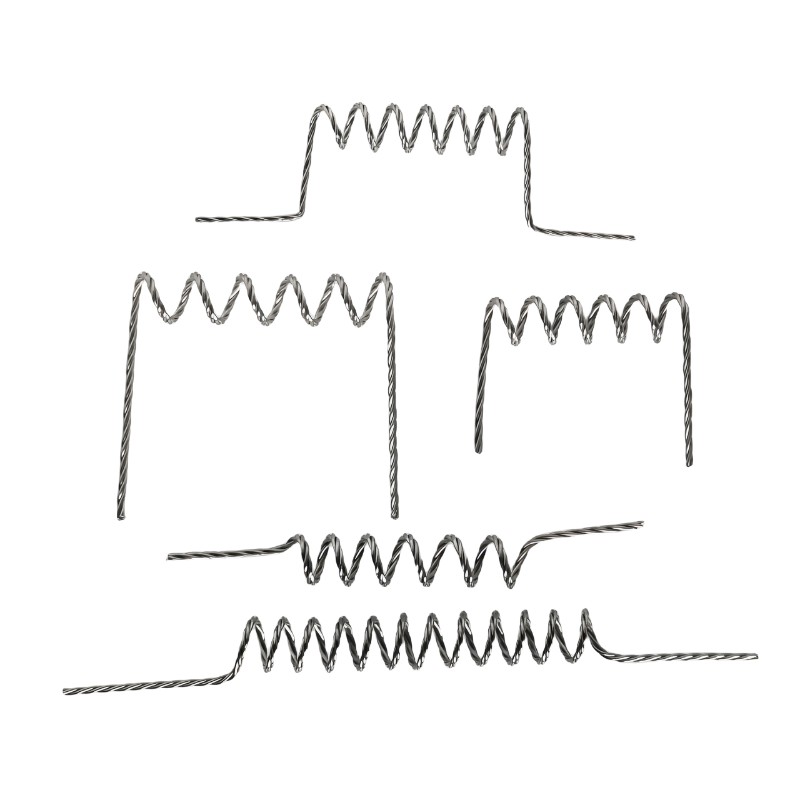

Mifananidzo yeTungsten Filaments

Mufananidzo wacho unongoratidza chete shinda dzakatwasuka uye dzakaita seU, zvichikubvumidza kugadzirisa mamwe marudzi nehukuru hweshinda dzakaita setungsten, kusanganisira shinda dzakaita sepeak-shaped, nezvimwewo.

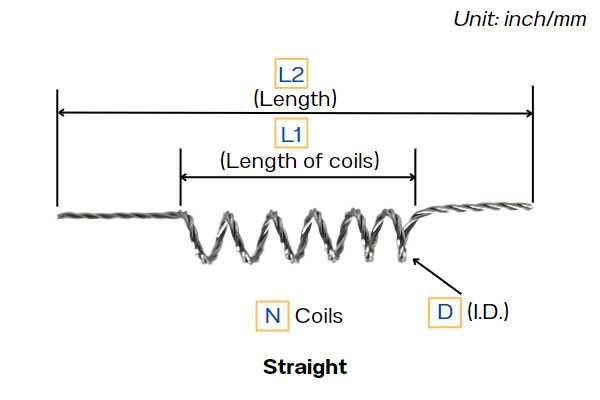

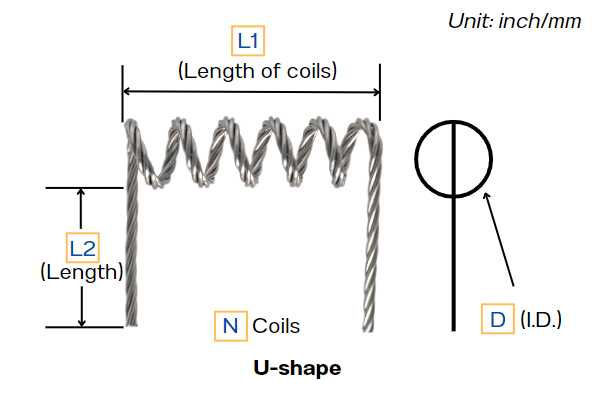

| Chimiro | Yakatwasuka, Yakaumbwa neU, Yakagadzirirwa |

| Nhamba yeTanda | 1, 2, 3, 4 |

| Makoiri | 4, 6, 8, 10 |

| Dhayamita yeWaya (mm) | φ0.6-φ1.0 |

| Kureba kweCoils | L1 |

| Kureba | L2 |

| ID yeCoils | D |

| Cherechedza: mamwe magadzirirwo uye maumbirwo efilament anogona kugadziriswa. | |

Tinogona kupa mhando dzakasiyana dzetungsten thermal filaments. Ndapota tarisai katalogi yedu kuti muzive nezvezvigadzirwa, uye tinokugamuchirai kuti mutibvunze.