Mutengo wefekitori wekutengesa weTungsten Wire Coil weThermal Evaporated

Mutengo wekutengesa wefekitori yeTungsten Wire Coil inodziya,

Tungsten coil inodziya,

Tungsten (W) Evaporation Coils, Tungsten Heaters

Chitofu chetungsten chine mabhenefiti ekuti chinonyunguduka zvakanyanya, hachigoni kunyunguduka zvakanyanya uye hachina kuchena zvakanyanya. Chine simba rekudzivirira kupisa uye kumanikidzwa kwakaderera kwemhepo uye chakakodzera zvikuru senzvimbo yekubuda kwemvura. Chakakodzera kushandiswa kwezvinhu zvine simba remvura zvakaita sealuminium, indium, uye tin kuti zvinyunguduke.

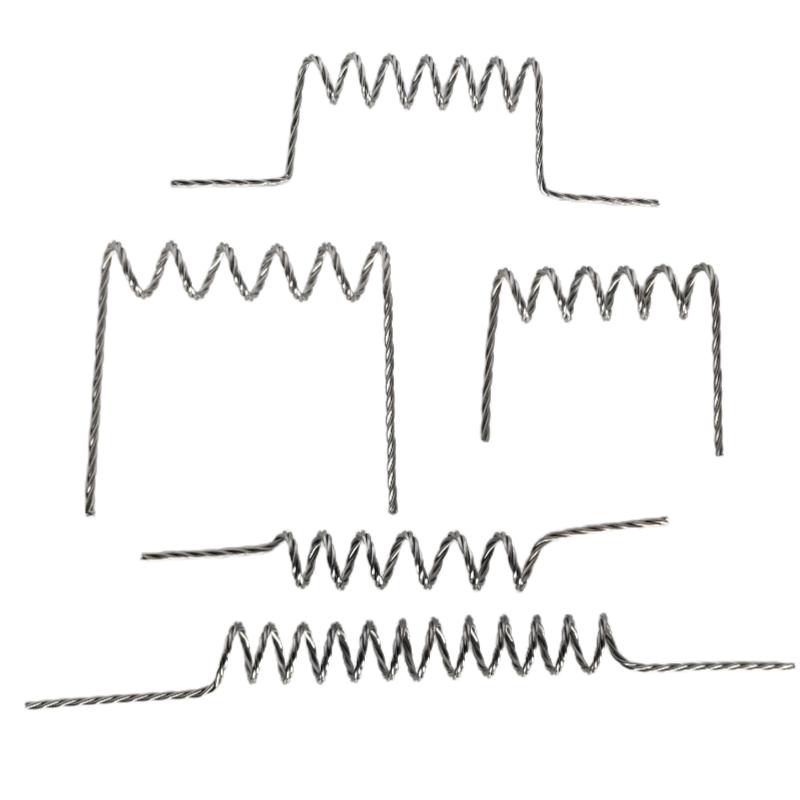

Makoiri eTungsten anoputika akagadzirwa newaya yeTungsten ine tambo imwe chete kana kuti ine tambo dzakawanda, iyo inogona kukochekwa kuita maumbirwo akasiyana zvichienderana nezvinodiwa pakuisirwa kana kupiswa kwemhepo. Tinopa vatengi mhinduro dzakasiyana-siyana dzewaya dzine tambo dzeTungsten, tinokugamuchirai kuti mubvunze.

Ruzivo rweTungsten Coil

| Zita rechigadzirwa | Tungsten Coil Heater/Evaporation Coil |

| Kuchena | W≥99.95% |

| Kuwanda kwevanhu | 19.3g/cm³ |

| Nzvimbo Yokunyunguduka | 3410°C |

| Tambo | φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, Inogona kugadziriswa. |

| MOQ | 3Kg |

| Kushandiswa | Kuputira kweThermal Evaporation |

Zvakanakira Zvedu

Chitofu chedu chetungsten chinodziya chine filament chinoshandisa simba shoma, chinogara kwenguva refu uye chinobatsira pakubuda kwemvura, uye chakakodzera mhando dzese dzemuchina wevacuum evaporation.

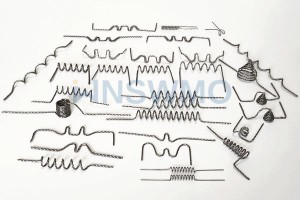

Kupatsanurwa kweTungsten Filament Heaters

• Mahita eCoil

• Mahita ebhasiketi

• Mahita eSpiral

• Mahita ePoint neLoop

Tinogona kupa mhando dzakasiyana dzeTungsten Thermal Filament Sources, unogona kudzidza nezvezvigadzirwa izvi kuburikidza nekatalogu yedu, tinokugamuchirai kuti mutibvunze.

| Chimiro | Yakatwasuka, U Shape, Inogona kugadziriswa |

| Nhamba yeTanda | 1, 2, 3, 4 |

| Makoiri | 4, 6, 8, 10 |

| Dhayamita yeWaya (mm) | 0.76, 0.81, 1 |

| Kureba kweCoils | L1 |

| Kureba | L2 |

| ID yeCoils | D |

| Cherechedza: mamwe magadzirirwo uye maumbirwo efilament anogona kugadziriswa. | |

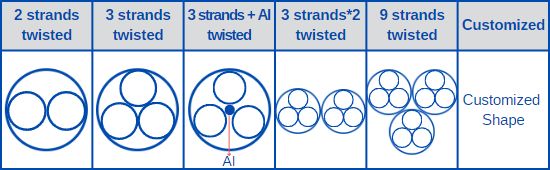

Matanho ewaya yakamanikana: φ0.76X3, φ0.81X3, φ1.0X3, φ1.0X2, φ0.81X4, φ0.81X3+Al, Inogona kugadziriswa.

Tinopa vatengi vedu mhinduro dzakasiyana-siyana dzekubatanidza waya dzetungsten. Munogona kugadzirisa zvinodiwa uye maitiro.

Tinopa manyuko emvura uye zvinhu zvekubuda kwemvura zvePVD coating & Optical coating, zvigadzirwa izvi zvinosanganisira:

| Matanda eElectron Beam Crucible Liners | Tungsten Coil Heater | Filament yeTungsten Cathode |

| Chinopfuta Kupisa Kwemvura | Zvinhu zveKubuda Kwemvura | Chikepe cheKubuda Kwemvura |

Hauna chigadzirwa chaunoda here? Ndapota taura nesu, tichagadzirisa dambudziko racho.

Kubhadhara & Kutumira

→KubhadharaTsigira T/T, PayPal, Alipay, WeChat Pay, nezvimwewo. Ndapota tauriranai nesu kuti muwane dzimwe nzira dzekubhadhara.

→KutumiraTsigira FedEx, DHL, UPS, zvinhu zvinotakura mugungwa, uye zvinhu zvinotakura mundege, unogona kugadzirisa hurongwa hwako hwekufambisa, uye tichakupawo nzira dzekufambisa dzakachipa kuti uzive.

Unoda kuziva zvakawanda nezvezvigadzirwa zvedu here?

Ndibatei

Maneja weKutengesa waAmanda│

E-mail: amanda@winnersmetals.com

Nhare: 0086 156 1977 8518 (WhatsApp/Wechat)

Kana muchida kuziva zvakawanda nezvemitengo yezvigadzirwa zvedu, ndapota taurai nemaneja wedu wekutengesa, achakupindurai nekukurumidza sezvinobvira (kazhinji mukati memaawa makumi maviri nemana), zvechokwadi, munogonawo kudzvanya "KUMBIRA VATENGESI VATENGESI", kana kutibata zvakananga nekutumira email (Email:info@winnersmetals.com).

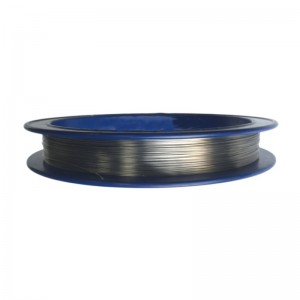

Uri kutsvaga zvinhu zvemaindasitiri zvinodzivirira ngura zvakanyanya uye zvakagadzikana pakupisa kwakanyanya? Zvinokurudzirwa kushandisa waya yedu yakamonyoroka yetungsten yakaputirwa ne vacuum, ine kugara kwenguva refu uye kugadzikana uye inogona kuchengetedza kushanda kwakasimba munzvimbo dzakasiyana-siyana dzakaoma. Tinosimbirira kushandisa tekinoroji yakaoma yekugadzira uye michina yekugadzira yepamusoro kuti tikupe zvigadzirwa zvemhando yepamusoro chete. Waya dzese dzakamonyoroka dzetungsten dzinogadzirwa zvakanaka uye dzinodzorwa zvakanyanya kuti dzive nechokwadi chekuti dzinoshanda zvakanaka uye dzinogara kwenguva refu pakugadzira kwako.

Kwete izvozvo chete, tinopawo sevhisi yepamusoro-soro. Tinotevedzera pfungwa yebasa rinotarisa vatengi. Pasinei nekuti une mibvunzo kana unoda rubatsiro, timu yedu yehunyanzvi ichafara kupindura mibvunzo yako uye kuona kuti unogutsikana. Kana ukasarudza zvigadzirwa zvedu zvewaya dzakaputirwa ne vacuum coated tungsten, uchagutsikana zvizere nemhando yebasa.