Molybdenum Crucibles yeE-Beam Source

Molybdenum E-Beam Crucibles

Molybdenum electron beam crucibles anoshandiswa mu electron beam evaporation process. Molybdenum crucible liners zvidziviriro zvakaturikidzana kana kuiswa kwakagadzirwa nesimbi yemolybdenum inoiswa mukati meiyo crucible kuti iwedzere kushanda kwayo uye kusimba mukupisa kwepamusoro. Kusarudza iyo yakakodzera crucible liner size inogona kukwirisa firimu deposition kunyatsoita uye kuderedza mutengo wekugadzira.

Molybdenum electron beam crucibles inowanzogadzirwa kubva kune yakakwirira-kuchena molybdenum simbi. Molybdenum ine yakakwira kunyungudika (2,620 ℃), yakanakisa yekupisa conductivity, uye kuramba kuvhunduka kwekupisa uye kurwisa kwemakemikari.

Isu tinopa molybdenum electron beam crucible liners mu4cc, 7cc, 15cc, 25cc, 30cc, 40cc, 100cc uye zvimwe zvakatemwa. Yedu molybdenum crucibles inogadziriswa kubva kune yakakwira-kuchena forged molybdenum rods, iyo inoratidzira yakanyanya kurongeka, kuchena kwepamusoro, kusasvibiswa, hupenyu hurefu, kutonhora kwepamusoro, uye yakanakisa kunyura uye kusagadzikana kwemarara.

Molybdenum Crucible Information

| Product Name | Molybdenum (Mo) Crucibles |

| Kuchena | 99.95% |

| Density | 10.2g/cm³ |

| Melting Point | 2620 ℃ |

| Kushanda Tembiricha | 1100 ℃-1800 ℃ |

| Production Process | Machined-Polishing |

| Application | E-Beam Evaporation, kushandiswa kweLab |

| Type | 4cc, 7cc, 15cc, 25cc, 30cc, 40cc, 100cc, Inogona kugadzirwa |

| MOQ | 2 zvidimbu |

Application

Molybdenum electron beam crucibles anoshandiswa zvakanyanya mutete firimu deposition application mumaindasitiri akasiyana:

• Semiconductor Manufacturing.

• Optical Coatings.

• Kugadzirwa kwemasero ezuva.

• Tsvakurudzo nekusimudzira.

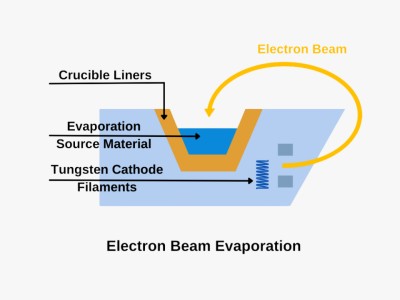

Nezve Electron Beam Evaporation Coating

Erekitironi beam evaporation method imhando yevacuum evaporation coating, iyo inoshandisa matanda erekitironi kupisa zvakananga zvinhu zvekubuda mumhepo pasi pemamiriro evacuum, kufambisa zvinhu zvekupupuma uye kuzvitakura kuenda kune substrate, uye condena pane substrate kuita firimu rakatetepa.

Electron beam evaporation inogona kunyungudika yakakwira kunyungudika zvinhu, zvine hupamhi hwekupisa kwekupisa, kukwira kwebeam ikozvino density uye nekukurumidza kubuda kwemhepo kupfuura zvakajairika kupisa kupisa evaporation. Iro firimu rakagadzirwa rakatetepa rine kuchena kwepamusoro uye hunhu hwakanaka, rinogona kudzora ukobvu zvakanyanya, uye rinogona kushandiswa zvakanyanya mukugadzirira kwakasiyana-siyana optical zvinhu matete mafirimu akadai seyepamusoro-kuchena matete mafirimu uye conductive girazi.

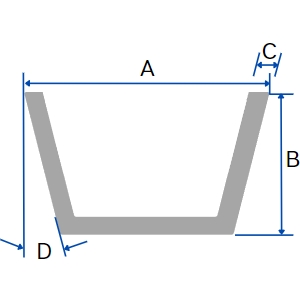

Molybdenum Crucible Dimensions

Mazano:

1. Iyo dhizaini ndeyezviyero zve crucibles, izvo zvinogona kugadzirwa zvinoenderana neanoenderana zvirevo.

2. Mamwe marudzi emacrucibles anogona kugadziriswa.

3. Kune vatengi vasina mifananidzo, tinogona kukuitira madhirowa pasina muripo uye simbisa zviyero zvakadzama.

| Homwe Volume | Top Diameter(A) | Urefu(B) | Kukora Kwemadziro(C) | kona(D) |

| 4cc | 0.885 mukati (22.48mm) | 0.595 mukati (15.11mm) | 0.093 mukati (2.36mm) | 15° |

| 7cc | 1.167 mukati (29.64mm) | 0.563 mukati (14.30mm) | 0.093 mukati (2.36mm) | 15° |

| 12cc | 1.334 mukati (33.88mm) | 0.768 mukati (19.51mm) | 0.093 mukati (2.36mm) | 15° |

| 15cc | 1.48 mukati (37.59mm) | 0.67 mukati (17.02mm) | 0.125 mukati (3.18mm) | 15° |

| 20cc | 1.673 mukati (42.49mm) | 0.768 mukati (19.51mm) | 0.093 mukati (2.36mm) | 15° |

| 25cc (4 Homwe) | 1.85 mukati (46.99mm) | 0.68 mukati (17.27mm) | 0.125 mukati (3.18mm) | 15° |

| 25cc (6 Homwe) | 1.633 mukati (41.48mm) | 0.94 mukati (23.88mm) | 0.125 mukati (3.18mm) | 15° |

| 30cc (ine dandemutande) | 1.92 mukati (48.77mm) | 0.81 mukati (20.57mm) | 0.093 mukati (2.36mm) | 15° |

| 30cc (pasina webhu) | 1.775 mukati (45.09mm) | 0.94 mukati (23.88mm) | 0.125 mukati (3.18mm) | 15° |

| 40cc | 2.03 mukati (51.56mm) | 1.02 mukati (25.91mm) | 0.125 mukati (3.18mm) | 15° |

| Inobvumira kugadzirisa kwemamwe saizi kana kugadzirwa zvinoenderana nedhirowa kuti isangane nezvido zvako. | ||||

Sei Tisarudze?

Isu tinokupa iwe yemhando yepamusoro yakachena molybdenum crucibles, mabhenefiti edu makuru ndeaya anotevera:

☑ Yakagadzirwa nepamusoro-kuchena molybdenum tsvimbo kuti ive nechokwadi chekuchena.

☑ Kugadzirwa kwehunyanzvi, kurongeka kwechigadzirwa kwepamusoro, uye nzvimbo inopenya.

☑ Nguva pfupi yekuendesa uye mutengo wakanaka.

☑ Diki shoma odha huwandu, tsigira kugadzirisa.

Neanopfuura makore gumi eruzivo rweindasitiri, tinokwanisa kugadzira molybdenum crucibles ine yakakwira density uye kuchena, zviyero zvakaringana, nzvimbo yakatsetseka, yakakwirira-tembiricha kuramba, uye corrosion resistance.

Macrucibles edu anoshandiswa nevatengi vazhinji pasi rese nekubudirira kukuru. Kunyangwe iri diki crucible yekushandiswa kwerabhoritari (10mm dhayamita) kana yakakura crucible yekushandiswa kwemaindasitiri (300mm dhayamita), tinogona kuigadzira.

Isu tinopa evaporation masosi uye evaporation zvinhu zvePVD coating & Optical coating, izvi zvigadzirwa zvinosanganisira:

| Electron Beam Crucible Liners | Tungsten Coil Heater | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Evaporation Material | Evaporation Boat |

Hauna chigadzirwa chaunoda? Ndapota taura nesu, tichazvigadzirisa iwe.

Unoda kuziva zvakawanda nezvezvigadzirwa zvedu?

Taura nesu

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Runhare: +86 156 1977 8518(WhatsApp/Wechat)

Kana iwe uchida kuziva mamwe mashoko uye mitengo yezvigadzirwa zvedu, tapota taura nemutungamiriri wedu wekutengesa, iye achakupindura iwe nokukurumidza sezvinobvira (kazhinji kwete kupfuura 24h), ndatenda.