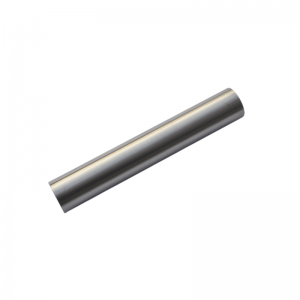

99.95% Yakagadzirwa Tungsten Tsvimbo Yakakwenenzverwa Nzvimbo

Tungsten (W) Tsvimbo

Tungsten tsvimbo dzinonyanya kugadzirwa netungsten simbi, iyo ine yakakwira kunyungudika, kuoma kwakanyanya, kusimba kwepamusoro, uye yakanakisa kupfeka kuramba. Izvi zvivakwa zvinobvumira tungsten tsvimbo kuti iite zvakanaka mukupisa kwakanyanya, kudzvanywa, uye nharaunda dzinoparadza.

Tungsten tsvimbo dzinoshandiswa zvakanyanya mumagetsi, aerospace, indasitiri yemakemikari, midziyo yekurapa, mechanic processing, uye mamwe minda. Muindasitiri yemagetsi, tungsten tsvimbo dzinowanzo shandiswa kugadzira ma electrode, macontacts, vacuum circuit breakers, uye zvimwe zvikamu; mumunda we aerospace, tungsten tsvimbo dzinoshandiswa kugadzira alloys epamusoro-tembiricha, rocket nozzles, uye zvimwe zvikamu; muindasitiri yemakemikari, tungsten tsvimbo dzinoshandiswa kugadzira simbi isingadziviriri zvinhu. midziyo nemapombi, nezvimwewo.

Tsvimbo dzedu dzetungsten dzakagadzirwa nehupfu metallurgy uye dzakagadzirwa. Iyo tungsten tsvimbo ine kuchena kwakanyanya, kusimba kwepamusoro, uye saizi yakanaka yezviyo. Isu tinopa tungsten tsvimbo neyakagadzirwa nzvimbo, alkali nzvimbo, uye yakakwenenzverwa nzvimbo. Ndapota taura nesu pamutengo unokwikwidza zvikuru.

Tungsten (W) Tsvimbo Ruzivo

| Products Name | Tungsten Rod/Bar |

| Giredhi | W1, W2 |

| Standard | ASTM 288-90, GB/T 4187-2017 |

| Kuchena | 99.95% |

| Density | 19.3g/cm³ |

| Melting Point | 3410 ℃ |

| Boiling Point | 5660 ℃ |

| Process | Sintering, Forging, Swaging, Rolling, polishing |

| MOQ | 1 kg |

Application

•Semiconductor ion implantation components.

•Magetsi mwenje sosi uye yemagetsi vacuum zvikamu.

•Industrial high-temperature choto refractory zvikamu.

•Electrodes ye argon arc welding uye resistance welding.

•Tungsten nhovo uye tungsten counterweight.

Dimensional Tolerances

| Diameter (mm) | Black Tungsten Rod | Yakaputswa Tungsten Rod | ||

| Diameter Deviation% | Roundness% | Diameter Deviation% | Roundness% | |

| 0.8≤d≤3.0 | ±2 | 2 | ±0.03 | 0.03 |

| 3.0 | ±2 | 2 | ±0.05 | 0.05 |

| 6.5 | ±2 | 2 | ±0.08 | 0.08 |

| 13.5 | ±2 | 2 | ±0.15 | 0.15 |

| 25 | ±2 | 2 | ±0.25 | 0.25 |

Unoda kuziva zvakawanda nezvezvigadzirwa zvedu?

Taura nesu

Amanda│Sales Manager

E-mail: amanda@winnersmetals.com

Runhare: +86 156 1977 8518(WhatsApp/Wechat)

Kana iwe uchida mamwe mashoko uye mitengo yezvigadzirwa zvedu, tapota taura nemutungamiriri wedu wekutengesa, iye achapindura nokukurumidza sezvinobvira (kazhinji kwete kupfuura 24h), ndatenda.